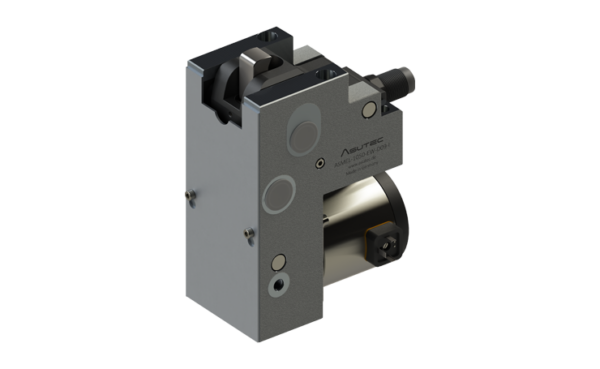

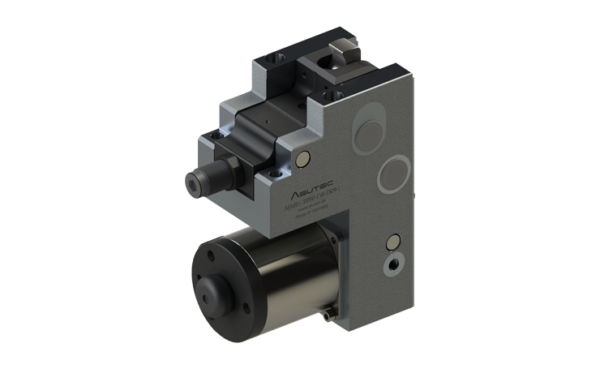

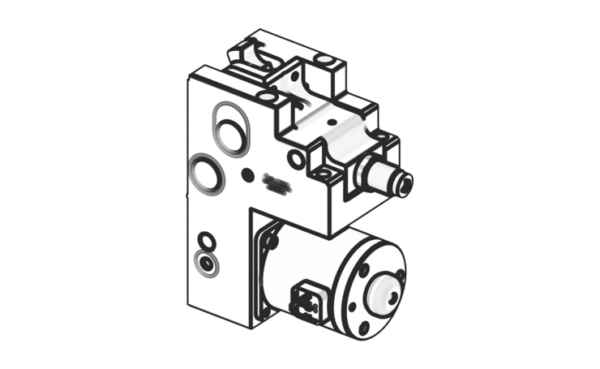

Stop module with damping ASMEL-1050

For stopping and separating of one or more accumulated workpiece carriers on a defined workpiece carrier stop surface.

The stoppers of the ASMEL-205 and ASMEL-1050 series differ from the stoppers of the ASMEL-200/-500/-680/-1000 series in that the stop performs a pivoting movement when damping and that the damping unit can be screwed out. So the damping effect can be adjusted. This means that lighter workpiece carriers can be damped and stopped with less propulsive force. The damping end position is reached more reliable.

Technical data

TYPE

TYPE

Electrical separating stop with self-adjusting damping unit

Aluminum basic housing

Stop plate made from hardened steel

Optimal damping of workpiece pallets up to a mass of 1050 kg

MAXIMUM RAM PRESSURE

MAXIMUM RAM PRESSURE

Dependent of:

– the friction between piece carrier and the transfer system.

– the friction between work piece carrier and the stop plate.

– the position of the work piece carrier stop surface.

– the ambient conditions (dust).

ELECTRICAL DATA

ELECTRICAL DATA

Voltage: 24 VDC

Duty cycle: 100%

Current consumption: 1.82 A

Function EW - single acting

Function EW - single acting

Lowering (opening) Electrically

Moving up (closing) vai spring force

INDUCTIVE POSITION DETECTION

INDUCTIVE POSITION DETECTION

Query the following states with inductive sensors M18x1 in clamp holders M24x1.5:

– Stop plate in stopping position (upper position)

– Stop plate in damping-end-position

TEMPERATURE RANGE

TEMPERATURE RANGE

+5°C up to + 60°C

SCOPE OF DELIVERY

SCOPE OF DELIVERY

The devices are delivered without accessories.

The accessories can be freely selected and adapted to the ambient conditions.

All accessories supplied are installed at the customer’s request.

MAINTENANCE

MAINTENANCE

No maintenance is required. The area around the stop plate must be clean and exempt from swarf to guarantee an exactly positioning of the workpiece carrier.