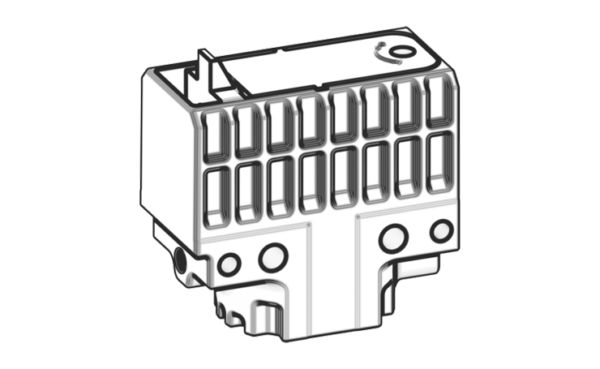

Stop module with damping ASMNG-15

For stopping and separating of one or more accumulated workpiece carriers a defined workpiece carrier stop surface.

Housing parts made of high strength, fiber reinforced polymer.

30% cheaper than the stop module ASM-15.

Made for small transfer systems like Bosch Rexroth TS1.

Technical data

EXECUTION AND WEIGHT

EXECUTION AND WEIGHT

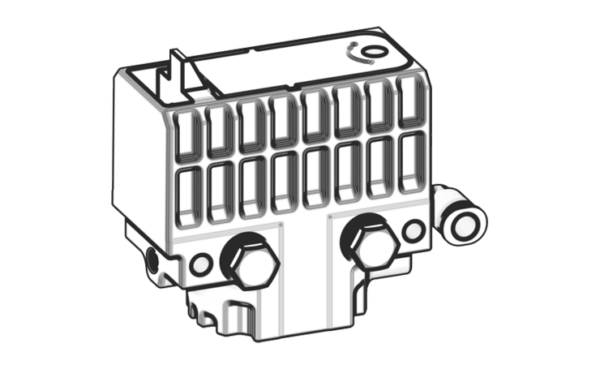

Device design: Basic housing made of hard anodized aluminum and stop plate made of brass.

Air damping system, adjustable with throttle screw.

Weights of the devices: ASMNG-15-EW-07: 0,17 kg

EFFECTIVE PISTON AREAS, FORCES

EFFECTIVE PISTON AREAS, FORCES

The forces are dependent on the pneumatic pressure, the piston surface and the spring force.

During the respective working movements, the following piston surfaces are subjected to compressed air:

Piston surface for lowering (EW-type): 421 mm²

Piston surface for extending the damping piston: 314 mm²

FUNCTION

FUNCTION

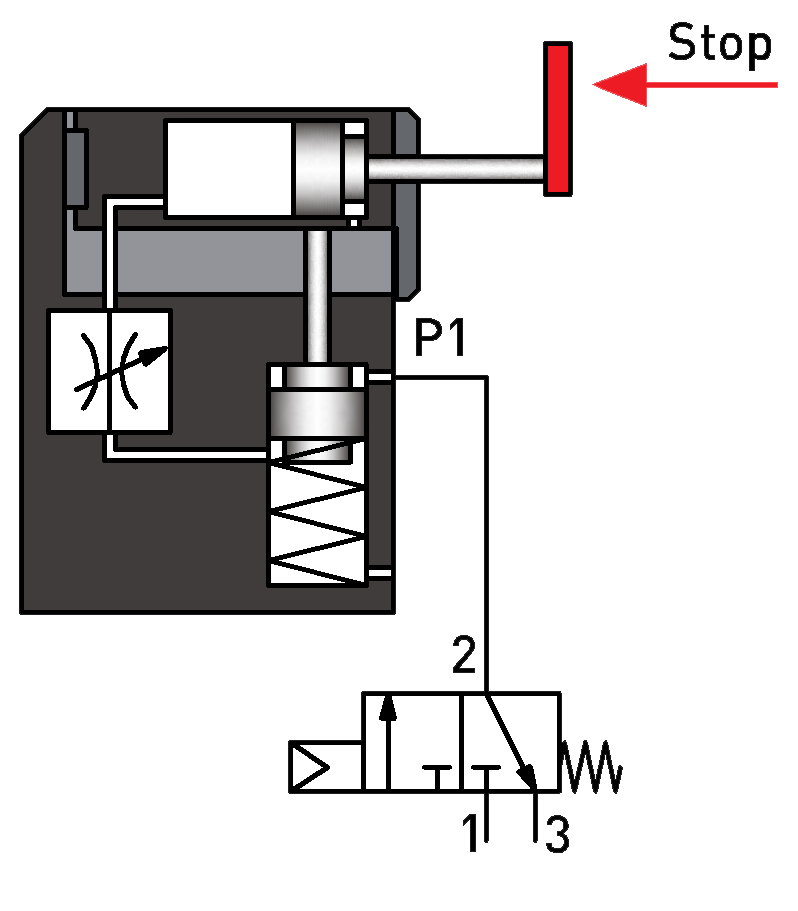

The pneumatically separator ASMNG is a separator with damping. If a workpiece carrier strikes against the stop plate of the separator, the air chamber is compressed and the compressed air escapes through the opening gap of the adjusting screw. Thus, the workpiece carrier is gently damped to a stop. The damping is with air and can be finely adjusted via a throttle screw. If the workpiece carrier will be damped, the stop plate will be pushed in. The stop plate will stay in this position. There are no forces that would try to move the stop plate even the workpiece pallet is not pushing against the stop plate. The extension of the stop plate is effected by an internal valve control in the separator, when lowering, when the separator has reached the lower position.

SPRING FORCES

SPRING FORCES

In its basic version “EW” = “single acting”, the separator ASMNG has a compression spring which moves the separator into its upper or raised position.

The spring forces are:

Raised position: F1 = 46 N

Lowered position: F2 =85 N

TEMPERATURE RANGE

TEMPERATURE RANGE

Standard version: +5°C to +60°C

AIR CONNECTION

AIR CONNECTION

The separators ASMNG are offered as single-acting variants. There is only one air connection (P1) for lowering the separator. This air connection is located on the back or front of the unit. Usually, the front air connection is closed by a blanking plug

OPERATING PRESSURE AND AIR CONSUMPTION

OPERATING PRESSURE AND AIR CONSUMPTION

Operating pressure 4 –8 bar

Single acting function:

Cylinder volume V for lowering + extending the stop plate:

ASMNG-15-EW-07: 3,1 cm³ + 2,2 cm³ = 5,3 cm³

The air consumption in liter (Nl) can be calculated by using a formula:

Q = V⋅(p+0,1)⋅0,01

Here is:

Q … air consumption in liter (Nl)

V … Cylinder volume (cm³)

p … Supply pressure in MPa (6 bar = 0,6 MPa)

For 0,6 MPa pneumatic pressure the air consumption for the ASMNG-15-EW-07 is Q = 0,037 Nl each cycle.