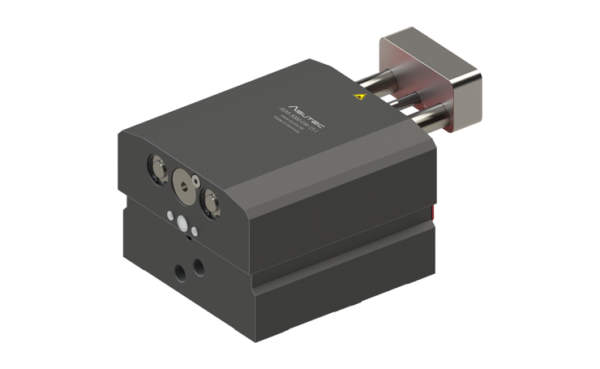

Stop module with damping ASM-3000

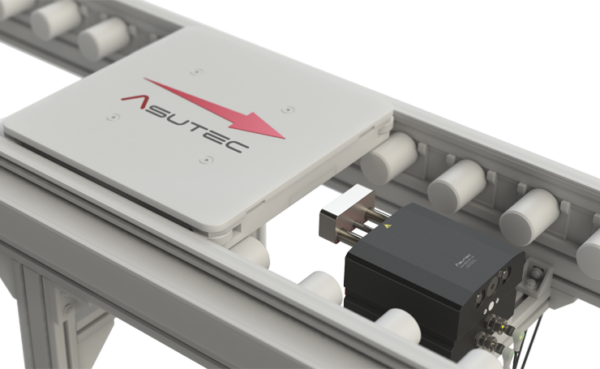

For stopping and separating of one or more accumulated workpiece carriers on a defined workpiece carrier stop surface.

Technical data

TYPE

TYPE

A very solid stopper with 15 mm lowering stroke.

Well protected against dripping liqudids.

Query option with inductive sensors as standard.

INSTALLATION

INSTALLATION

Fastening of the stopper by screwing from below with 6x screws M10.

DAMPING

DAMPING

Self-adjusting hydraulic damping unit

Damping stroke: 46 mm

PRODUCT WEIGHT

PRODUCT WEIGHT

ASM-3000-…-15-I: 12,5 kg

PROPULSIVE FORCE

PROPULSIVE FORCE

In order to ensure a perfect lowering movement of the stop module, the following propulsive forces must not be exceeded:

ASM-3000 – FRmax = 2075 N

In order to ensure that the stop plate reaches the damping end position, the following minimum propulsive forces must not be less than FRmin = 75,5 N

FUNCTION

FUNCTION

When a workpiece carrier hits the stopper’s stop, it is stopped in a dampened manner until it comes to a standstill.

Damping is provided by a self-adjusting hydraulic damping unit. This damping unit cannot be adjusted externally.

If the workpiece carrier will be damped, the stop plate will be pushed in.

The stop plate will stay in this position. There are no forces that would try to move the stop plate even the workpiece pallet is not pushing against the stop plate.

The extension of the stop plate is effected by an internal valve control in the stop module, when lowering, when the stop module has reached the lower position.

FUNCTION EW

FUNCTION EW

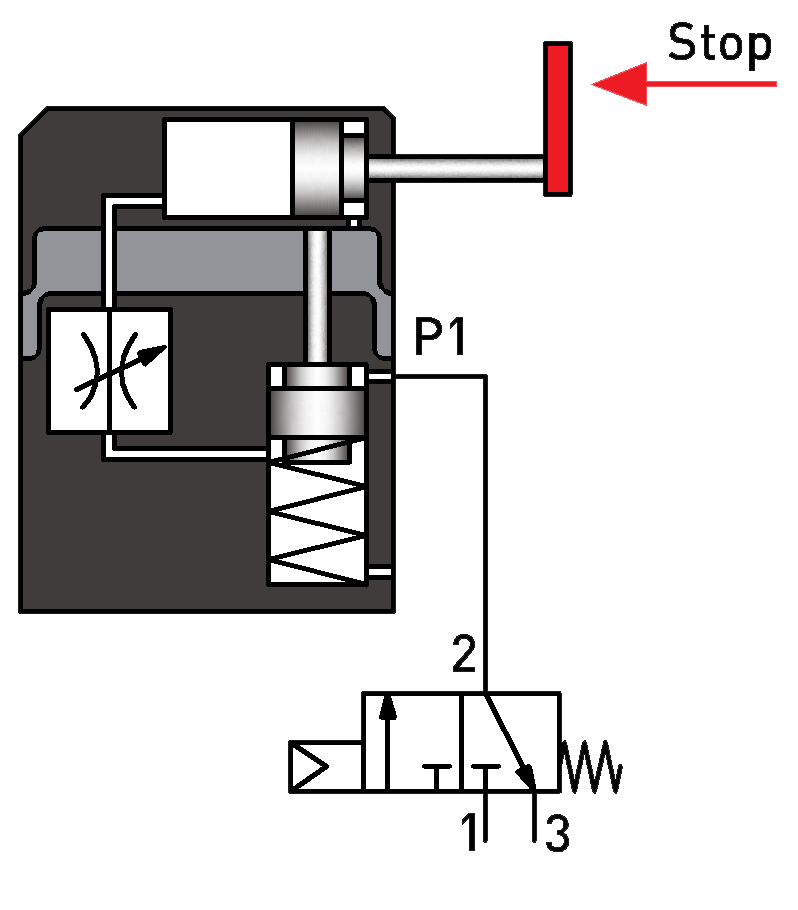

EW (single-acting): The lowering of the stop module is done by pneumatic pressure.

When the stop module has reached the lowered position, then the stop-damping-

piston is automatically extended.

In the unpressurized state, the stop module moves upwards into the blocking position by a spring and the next workpiece carriers can be stopped.

FUNCTION DW

FUNCTION DW

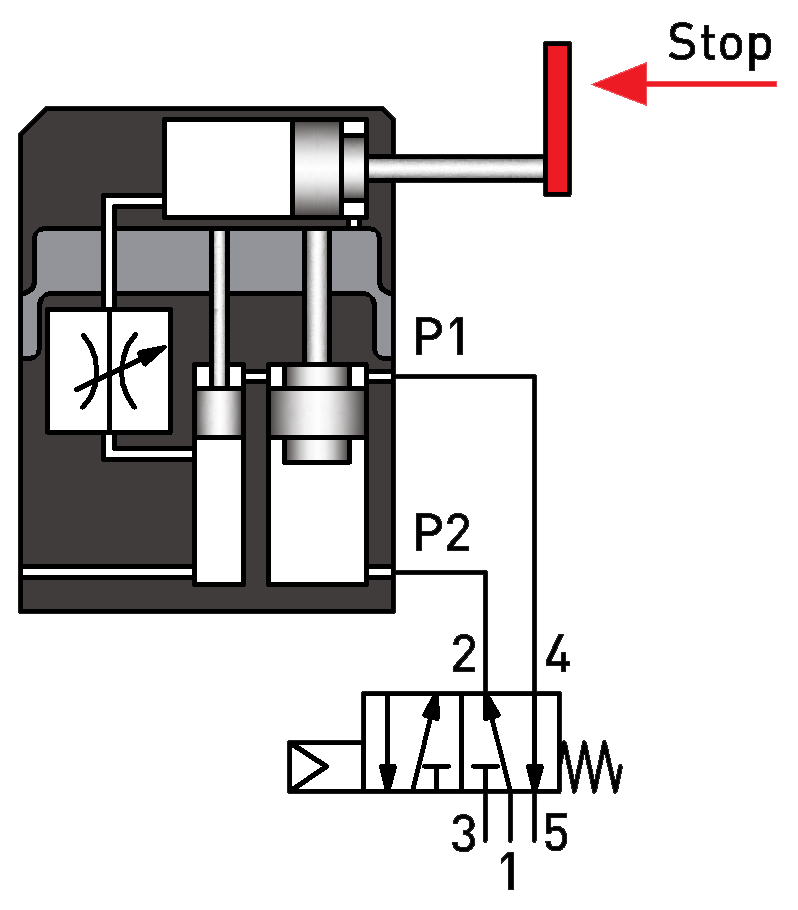

DW (double-acting): The lowering and raising of the stop module is done by pneumatic pressure.

When the stop module has reached the lowered position, then the stop-damping-piston is automatically extended.

In unpressurized state the stop module keeps his last reached position. The stop module has no spring. This increases the lowering force.

TEMPERATURE RANGE

TEMPERATURE RANGE

+5°C to +60°C

PNEUMATIC CONNECTION

PNEUMATIC CONNECTION

The stopper is lowered with the air connection P1.

In the DW version the air connection P2 is used to move the stopper up into the blocking position.

FURTHER TECHNICAL INFORMATION

FURTHER TECHNICAL INFORMATION

See „Data sheet / operating manual”

in the “Downloads” area